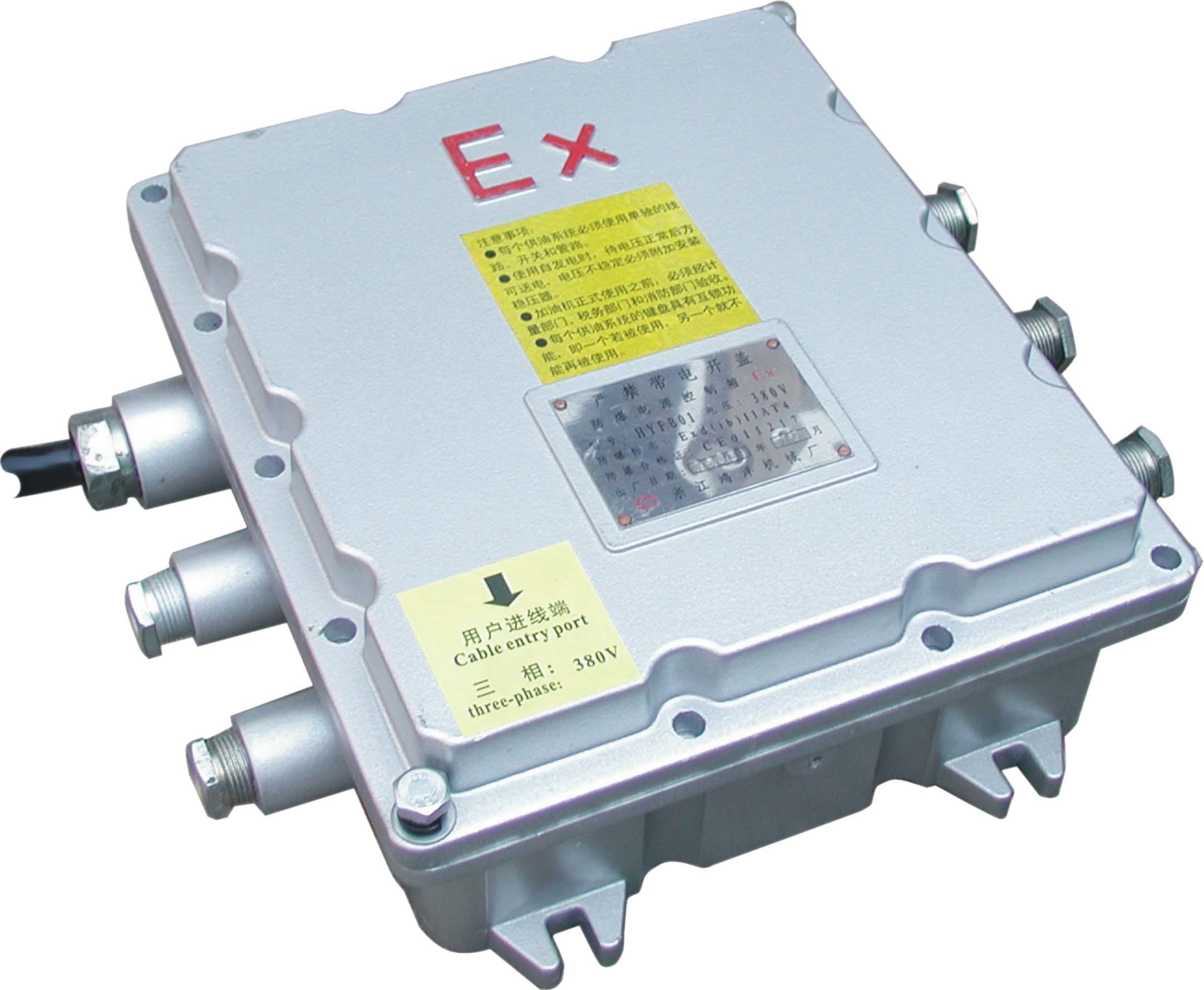

Designed to meet UL and NFPA requirements for hazardous location certifications, this actuator features a unique installation supervision system that reduces the number of potential leak points. It also uses design features and materials that can withstand highly corrosive environments while providing proper flame paths.

Hazardous locations are areas where explosive gases, combustible liquid-produced vapors, combustible dusts, or ignitable fibers and flyings exist either continuously or for long periods of time. Electrical equipment in these areas must be protected against explosions.

Safety Features

The UL Class I Division 1 designation means this electric actuator is suitable for use in hazardous locations as defined by the North American UL (Underwriters Laboratories) or ATEX (Europe/International) systems. These are locations where there is a risk of an explosion due to the presence of flammable gases, vapors or liquids in concentrations high enough to cause ignition.

Electrical equipment in such a hazardous location must be designed to eliminate or contain the possible ignition source, and that is where explosion proof electric motors come into play. These are motors that are specifically engineered and tested to withstand internal explosions, keeping them contained and preventing flames or other ignition sources from spreading into the surrounding area.

This explosion-proof servo motor has hermetically sealed contacts that are rated to avoid corrosion in hazardous environments and prevent dust from igniting. It also features a pry tamper loop for protection against tampering and terminal strip connections that are hermetically sealed to prevent accidental short circuiting.

Design

Explosion proof equipment is designed to prevent combustible dust, gas or vapors from reaching the outside environment, and to contain an internal explosion. This is critical in industries like mining, oil and gas refining, or flour mills where combustible materials are present. Despite the common misconception that explosion-proof equipment can survive an external blast, it was never designed to do so. Instead, it was engineered to ensure that the motor enclosure cannot reach a temperature high enough to ignite combustible dust, gases or vapors within.

Built with a heavy duty enclosure that meets rigorous UL and CSA tests, this hazardous location actuator is designed to operate small ball valves (2″ and smaller), dampers or similar quarter-turn devices. Internal components are plated with a passivated stainless steel to resist highly corrosive environments and provide a proper flame path. This design reduces potential leak points, enhancing the overall reliability of the system. It also includes integration of installation supervision technology and a force output that can be matched to specific fire suppression system operating pressures.

Materials

Explosion proof servo motors are built to operate safely in hazardous locations. They’re often used on oil and gas rigs, or in chemical processing facilities dealing with volatile substances. They are also found in food and beverage facilities dealing with flammable dust or vapors.

They are designed to withstand internal explosions by preventing ignition sources such as sparks or overheating. They are encased in sturdy housings made of non-sparking materials and have long passageways to cool gases that would otherwise ignite.

The enclosure on this hazardous location actuator meets rigorous UL and CSA requirements and features a 2 mm pitch with six full threads to reduce the risk of leak points. The design and materials used to construct the enclosure are also suited for highly corrosive environments.

This explosion proof electric actuator is rated for Zone 0 and Class I hazardous locations and is suitable for quarter-turn operation of ball valves, butterfly valves, plug valves, and dampers. They are power-to-open and power-to-close. They stay in their last known position with loss of power and are stopped by reversing continuous signals or internal cams striking limit switches.

Installation

When operating in a hazardous location that has a potential for explosive atmosphere created by flammable gases, combustible liquid-produced vapors, or ignitable fibers, dust or flyings, electrical equipment must be designed to prevent an explosion from occurring inside the motor enclosure. These explosion-proof motors are called Class I, Division 1 rated.

Unlike other UL listed actuators, these hazardous location actuators meet a broad range of hazardous location certifications with innovative design features and materials to resist highly corrosive environments, ensure a proper flame path, and provide easy installation. Additionally, these units have dual conduit openings for through wiring and can be mounted from any side.

The unit is powered to open via a continuous voltage signal and is stopped by internal cams striking limit switches. When power is switched off, the motor automatically stays in last known position. Alternatively, the unit can be controlled manually via two auxiliary dry contact limit switches. Two 1/2″ NPT threaded ports allow Div 1 rated glands (not included). Four production inspections are performed for additional safety.Explosion Proof Actuator UL Class 1 Div 1