The [[central processing unit|CPU]] and the [[graphics processing unit|GPU]], two key components in a computer, generate a lot of heat while running programs. They must be cooled in order to keep operating temperatures below dangerous levels.

Cooling is accomplished through both integral and peripheral means. Examples of the latter include fans to draw and blow air through a case, as well as CPU coolers.

Heat Sinks

The central processing unit and the graphics processor (if your computer has one) generate a lot of heat. Without appropriate cooling, these components may overheat and malfunction or even fail. To prevent this, they need adequate heat dissipation devices, such as a heat sink.

Heat sinks are metal thermal conductors that carry away excess heat from the CPU. They come in different shapes and sizes, but they all have something in common: high thermal conductivity. Typical materials are aluminium and copper.

A heat sink’s performance is affected by a number of factors, including air velocity, choice of material, fin design and surface treatment. Thermal paste is also necessary to improve heat transfer between the CPU and the metal of the heat sink. This is essentially a liquid, usually made from copper or aluminium, which fills the tiny gaps between the two components and facilitates heat flow between them. This allows the CPU to operate at higher speeds and to run for longer periods of time before throttling kicks in.

Fans

A CPU fan helps to disperse heat from the processor. Most PCs come with fans installed on the CPU and GPU that help to keep temperatures low. However, adding additional fans can really boost performance and help to maintain optimal CPU temperatures.

Cooling fans can also help with the temperature of other components, such as RAM. Most modern memory chips generate enough heat that active cooling is necessary. This typically involves a small fan positioned above the memory modules.

A motherboard may have integrated fans that can be monitored and controlled with BIOS settings or third-party software tools. However, it’s best to have case fans that pull air in from the front and push air out through the back or top of the case. This configuration allows for full circulation of cool air through the entire system, allowing for proper and effective cooling. It’s also a good idea to regularly clean fan dust and manage cables to avoid blockages, which can also impact airflow.

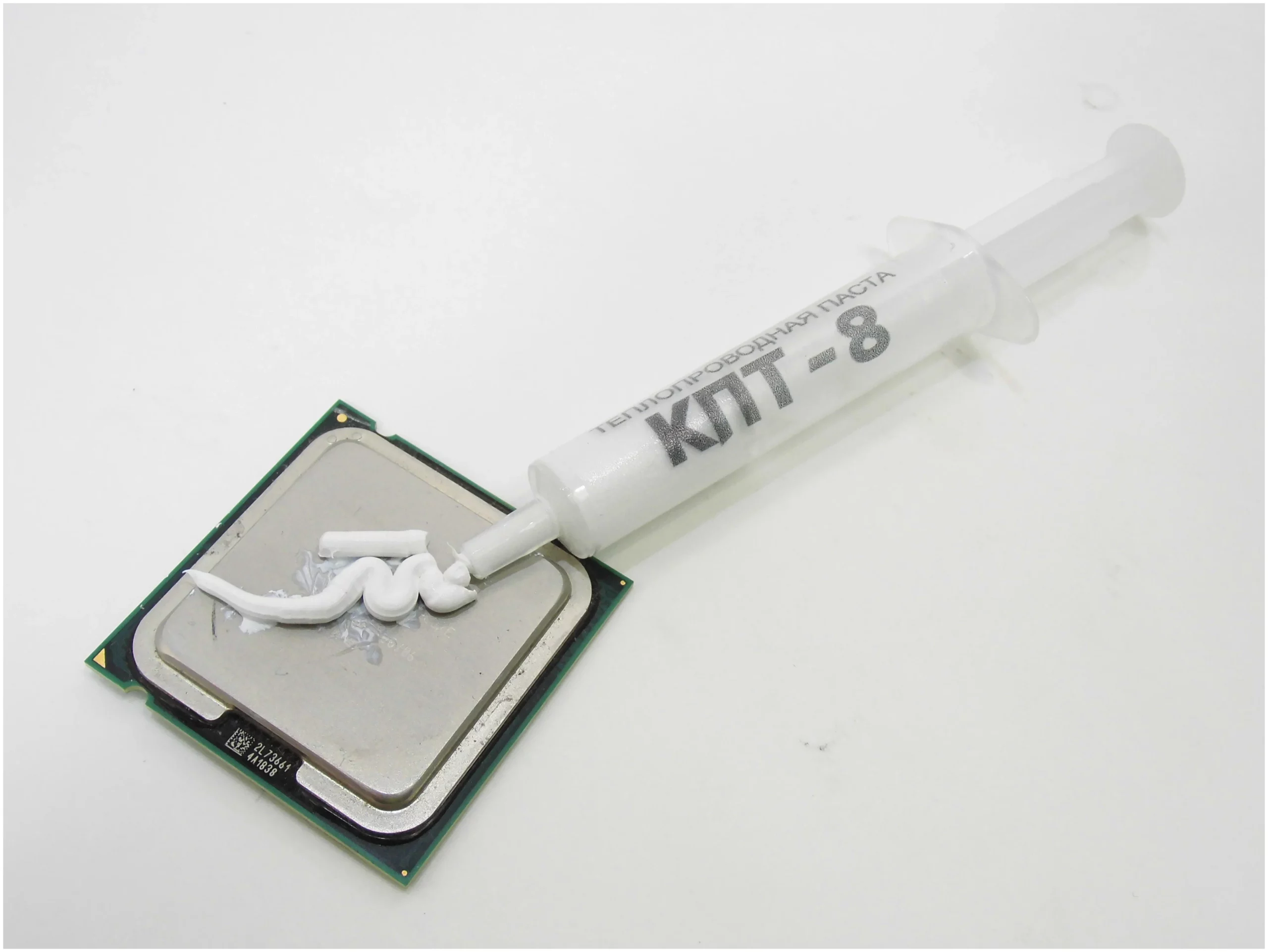

Thermal Paste

Thermal paste fills in microscopic gaps on the surface of your CPU and heat sink to prevent air from interfering with the transfer of heat. It is one of the most important components to have on hand when assembling or replacing your PC, yet many treat it as an afterthought.

When applying thermal paste, you want to avoid using a finger as the oil from your fingers can damage the surface and cause performance issues. Instead, use cotton swabs that are dampened with isopropyl alcohol.

Apply a line of thermal paste to the center of the IHS and let the pressure of the cooler spread it out as you secure it. Both the single dot and the thick line methods had fewer air bubbles, but still had some, which is expected. Just be sure to double-check your work to make sure that there is no extra thermal paste squirting out from the sides of your CPU once you’re finished.

Cooling Slots

The cpu cooling slots are used to direct cool air into the hot components to help prevent them overheating. They also enhance the flow of air to other parts of the computer like the graphics cards. Some modern designs use a coolant slot purge to further improve cooling and increase the power efficiency of the CPU.

A series of experimental studies have been conducted to investigate the effect of various slot geometries and flow conditions on endwall adiabatic film cooling effectiveness in subsonic transonic wind tunnel experiments. The research has focused on analyzing the effects of the cooling hole shape and size, flow conditions, and the design of the coolant slot geometry on endwall adiabatic film cooling performance.

The study investigated a variety of different slot geometries including plain slots with straight and tapered lands, and barchan-dune-shaped slot designs. The experiments were performed at a single-passage transonic wind tunnel using the pressure sensitive paint (PSP) technique. The PSP technique allows high resolution full surface adiabatic film cooling effectiveness distributions over the cutback surface and top of the lands to be recorded.